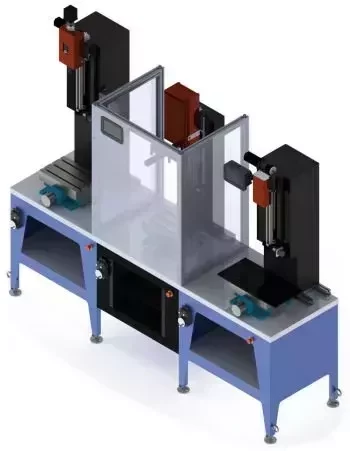

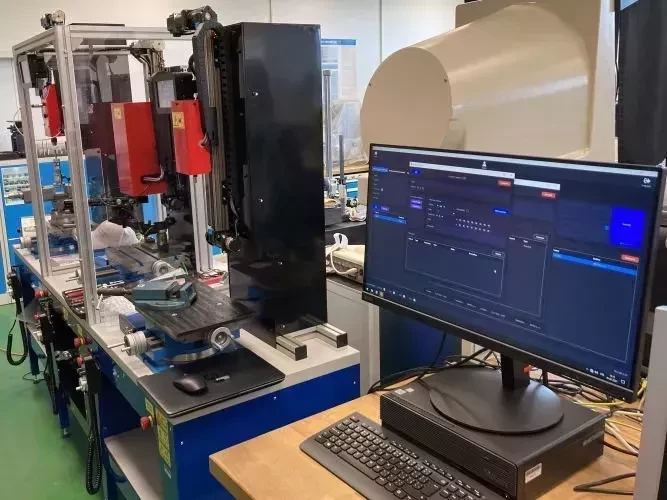

Custom development of test machines

Scope of activity

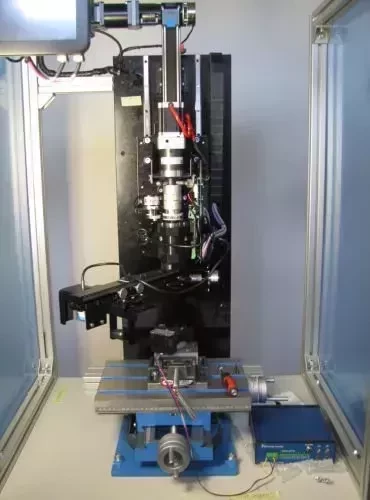

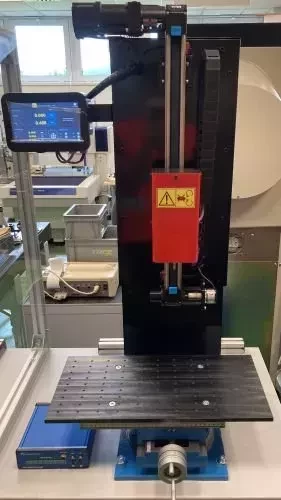

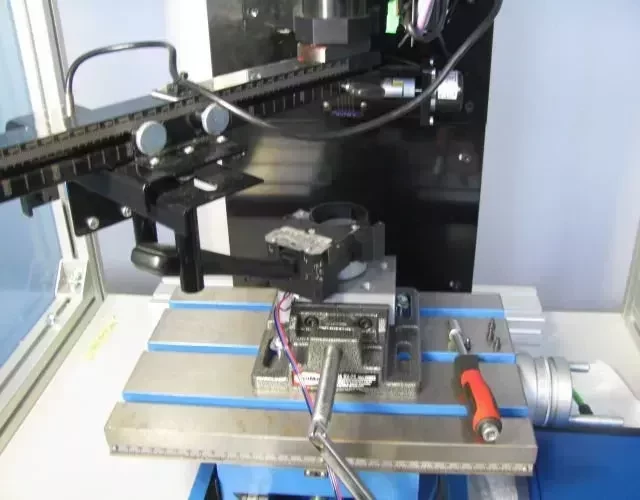

- Design and production of equipment - test and measuring machines, "space" applications, 1 - 6 axis machines with an accuracy of 0.01 mm - with data output.

- Advanced calculations (MKP or FEM) and simulations

- heat conduction - heating or cooling, max./min. operating temperatures for individual parts

- modal analysis - natural frequency x excitation from the machine / means of transport

- strength analyses

- harmonic analysis - resistance to harmonic/random excitation or shock

- Design of prototypes including production from a part to a functional machine with certification according to standards

- Design of PCBs

- We also design optomechanical assemblies

- We program in C++ and C# but we can also work with FPGA or CPLD embedded systems running under Linux OS

- Machine learning - 1D and 2D signal processing using machine learning techniques (artificial neural networks, regression and classification models)

- Signal processing - multivariate analysis, filtering, statistical evaluation

- Image processing - OpenCV, machine learning

Test machines for measuring quantities

- Tensile tests (0 - 1 kN)

- Pressure tests (0 - 30 kN)

- Torsion tests (0 - 500 Nm)

- Cyclic stress (durability test)

- Gas and liquid pressure measurement

Electric functionality

- Measurement of waveform of analog and digital signals with selectable level

- Measurement of status variables including bus decoding

- Measurement of overshoot and response of buttons

- Cyclic and reliability tests with statistical evaluation

- Electric strength tests on a stressed sample

- Implementation of special communication protocols for any sensors

We can perform designs according to the standards: ISO EN 12 100, EN 610 10, MIL 810, RTCA DO 160 and others.